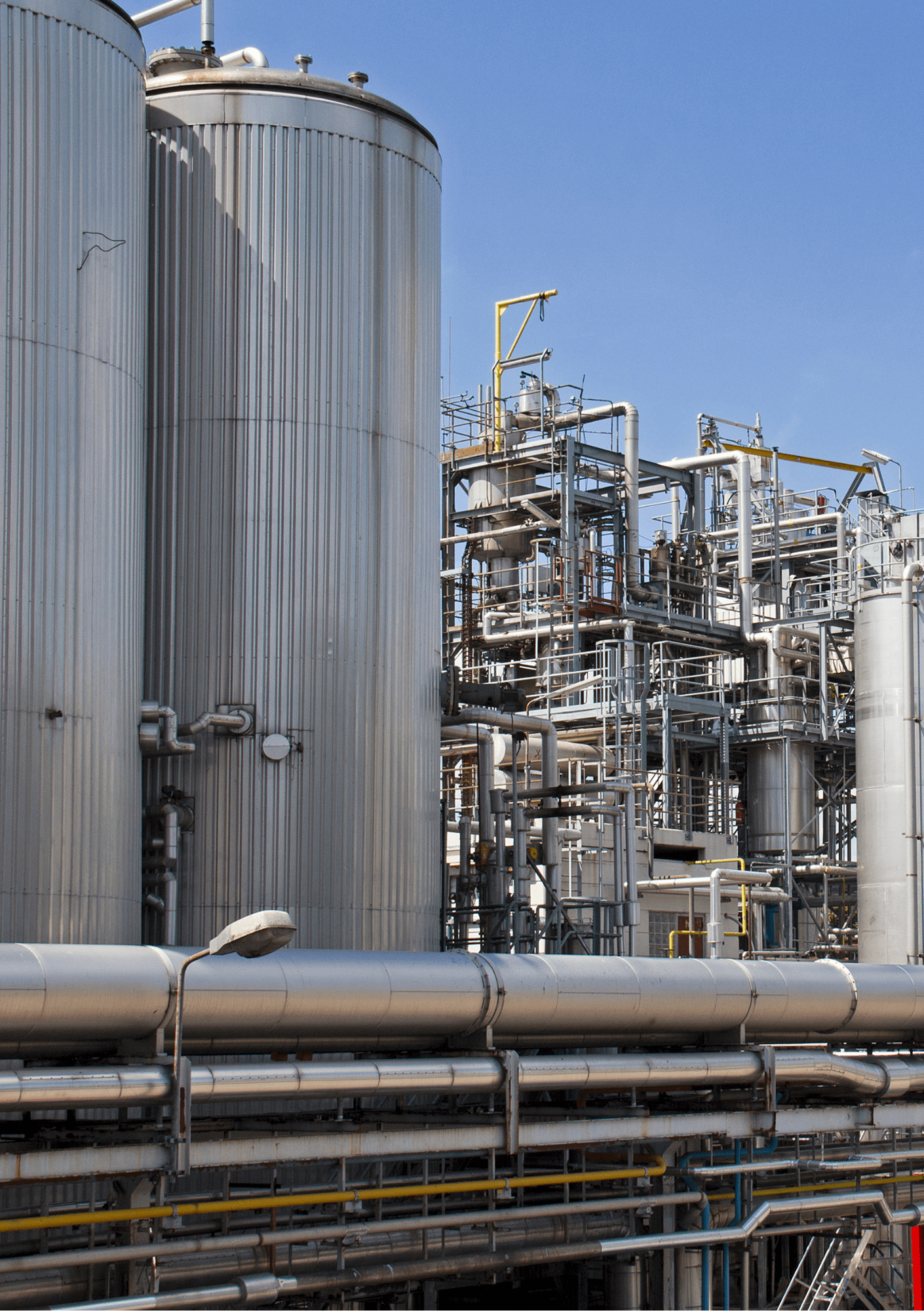

Our mission is to empower process plants in their transition to sustainable operations through customised energy efficient solutions.

Our engineers utilise energy assessment tools to identify opportunities that will reduce operations Scope 1 emissions for process and industrial plants.

We focus on energy reduction, energy recovery and recycling, and renewable energy integration. Whether it is to meet your Net Zero or Zero Carbon targets, or to cut energy usage costs, Distill-Re is here to support your project.

Based in Edinburgh, our team of experienced, chartered engineers provide cradle-to-grave solutions to our clients.

We understand your requirements and current processes that enable us to identify opportunities and carry out energy analysis.

We carry out detailed design, select suppliers and technologies and develop scope for mechanical, electrical and controls integration

With our sister company IDEA, we provide end-to-end solutions taking full responsibility of engineering, procurement, construction and commissioning aspects.

It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout.

info@distillre.co.uk

Contact us to see how we can support your first or next energy recovery project!

Founder & Director

Co-Founder & Director

Co-Founder & Director

Feasibility Study for a top-tier COMAH site with various processes and multi-megawatt heating and cooling requirements to achieve net zero.

Pinch Analysis for a grain distillery with multiple heat sinks and heat sources to optimise energy consumption.

FEED study for a manufacturing site to replace multi megawatt hot water boilers with high temperature industrial heat pumps.

Engineering & Procurement Management for achieving water reduction for a major maltings site through recycling and process modifications including delivery of process safety studies.

Development of design and selection of heat pumps including mechanical vapour recompression (MVR) for a malt distillery with maltings onsite.

Design a combined heating and cooling heat pump system for controlling the spirit temperature for bottling year-round.

Monday – Saturday

12:00 pm – 14:45 pm

Sunday – Thursday

17:30 pm – 00:00 pm

Friday – Saturday

17:30 pm – 00:00 pm

Copyright © 2024 Distill-RE. All rights reserved.